I can cross “tour an insulin manufacturing facility” off my bucket list.

I can cross “tour an insulin manufacturing facility” off my bucket list.

It was absolutely mind-blowing.

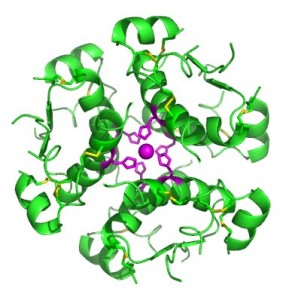

There is a lot of science involved, much of which I am not quite bright enough to understand. But the basic idea is that they start with some E. coli bacteria that is modified to produce insulin as it grows, then it is harvested, the insulin is stripped out, purified, packaged up and delivered to us.

One of the best places I could find that talks about how cells work actually used insulin as an example of biotechnology. From an article at HowStuffWorks.com:

To create insulin inexpensively, the gene that produces human insulin was added to the genes in a normal E. coli bacteria. Once the gene was in place, the normal cellular machinery produced it just like any other enzyme. By culturing large quantities of the modified bacteria and then killing and opening them, the insulin could be extracted, purified and used very inexpensively.

That makes it sound so simple, and I find it ironic that they used the word “inexpensively” more than once. There was nothing inexpensive about what I saw. Maybe it’s a relative term? Comparing it to the process of killing cows and pigs and harvesting insulin from their pancreases? On that note, I had trouble picturing the land we were visiting being a large slaughterhouse no more than thirty years ago.

I also learned that the first insulin made using this method of inserting human genetic instructions into a bacterium at Lilly was made possible through a partnership with Genentech (now owned by Roche).

Big and Small

I couldn’t wrap my brain around the quantities involved, so I’m going to describe it using very general ideas.

Imagine growing grass on a field the size of a few football fields. You start with nothing but space. You get the soil and prepare it, plant the proper seeds, then nurture the growing seeds until they’ve grown up into tall stalks of grass. But only a tiny portion of that grass stalk is the part you need. Imagine the entire grass stalk representing 100%, but you only need the 33% piece and 35% piece. The rest is useless to you (but you wouldn’t have those two specific parts without the whole).

Imagine growing grass on a field the size of a few football fields. You start with nothing but space. You get the soil and prepare it, plant the proper seeds, then nurture the growing seeds until they’ve grown up into tall stalks of grass. But only a tiny portion of that grass stalk is the part you need. Imagine the entire grass stalk representing 100%, but you only need the 33% piece and 35% piece. The rest is useless to you (but you wouldn’t have those two specific parts without the whole).